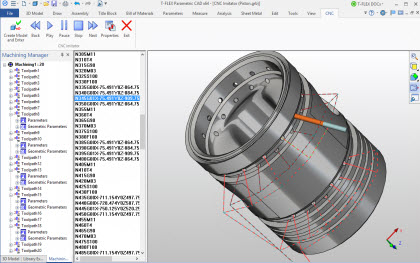

Fully integrated manufacturing add-on to T-FLEX CAD for generating NC programs as well as toolpath verification and machine simulation.

System for a Full Range of Machine Tool Applications

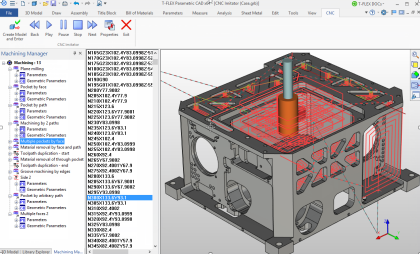

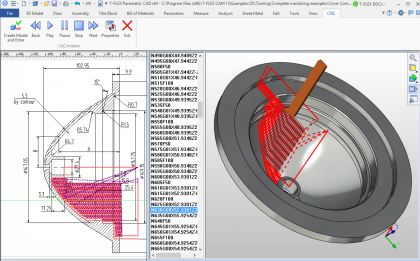

Parametric CAD/CAM integration

Fully associative geometry and toolpaths let you modify the geometry or machining parameters and immediately get an accurate, updated toolpath. With the single-window integration of

Wire EDM

The same features can be applied for waterjet, laser or plasma cutting.

Production Turning

Whether you are looking for a CAM system to automate your traditional turning "from roughing and grooving to threading and finishing" for faster, more accurate results, or to maximize your multi-axis machine tool investment,

Whether you are looking for a CAM system to automate your traditional turning "from roughing and grooving to threading and finishing" for faster, more accurate results, or to maximize your multi-axis machine tool investment,

Drilling and Hole Making

Drilling, deep-hole drilling, peck drilling, reaming, boring, tapping, and many other point-to-point pre-programmed and canned machining cycles are available as well as customizable drilling cycles.

2.5D Milling/Engraving

3D Milling

You can specify boundaries to limit the cutting region, perform area machining of solid bodies or their cross sections, apply special algorithms for edge/flange finishing, and calculate toolpath for helical circle milling. The program offers support for constant Z-levels and equidistant approaches producing particularly smooth surface finishes. Pencil cutting allows to machine sharp or filleted details even if they have not been filleted.

You can specify boundaries to limit the cutting region, perform area machining of solid bodies or their cross sections, apply special algorithms for edge/flange finishing, and calculate toolpath for helical circle milling. The program offers support for constant Z-levels and equidistant approaches producing particularly smooth surface finishes. Pencil cutting allows to machine sharp or filleted details even if they have not been filleted.

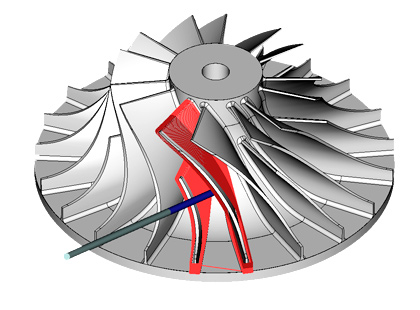

Advanced 5D Milling

Toolpath generation for complex surfaces with double curvature is also supported on the base of "composite surface" single parametric area for tool orienting.

Toolpath generation for complex surfaces with double curvature is also supported on the base of "composite surface" single parametric area for tool orienting.

5D Drilling

5-axis drilling lets you cut holes approaching the part from any angle. It quickly rotates the tool to line up with the hole, reducing the need to reset the part, producing huge time savings and increasing accuracy and surface finish.

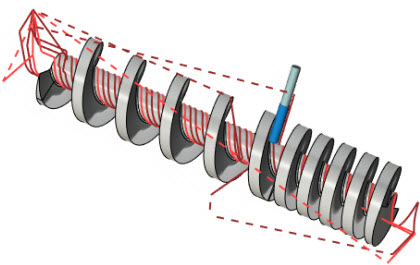

Cam-shaped Milling

The special milling of cam-shaped forms is aimed at machining surfaces of revolution or their sectors. The concentric cutting passes for this type of machining are oriented orthogonal to the axis of cam rotation. The forming tool movement is defined by cam geometry and corresponds to the pusher motion law of cam mechanism.

NC Simulation and Verification

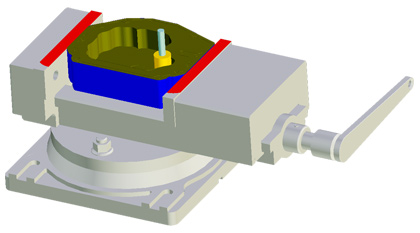

Flexible Tooling Options

Postprocessing Capabilities