Wide spectrum of specialized analysis tools to help engineers virtually test and analyze complicated parts and assemblies.

T-FLEX Analysis offers a wide spectrum of specialized analysis tools to help engineers virtually test and analyze complicated parts and assemblies. It employs the finite element method for performing static, frequency, buckling, thermal, optimization, fatigue and other analysis. T-FLEX Analysis shows how a model will perform under real-world conditions before it is built.

T-FLEX Analysis offers a wide spectrum of specialized analysis tools to help engineers virtually test and analyze complicated parts and assemblies. It employs the finite element method for performing static, frequency, buckling, thermal, optimization, fatigue and other analysis. T-FLEX Analysis shows how a model will perform under real-world conditions before it is built.

Associative Model

The CAE model is fully associative to the design model, since it uses native T-FLEX CAD geometry. T-FLEX Analysis ensures that the very latest design information is available for simulation without the need for any time-consuming geometry translation or data re-creation. Design changes made in a model are automatically updated for analysis calculations. Meshing is automatic and completely adaptive to even the most complex model geometry.

User Interface

Complete integration with T-FLEX CAD means that T-FLEX Analysis users can perform design analysis, simulation and optimization directly from their T-FLEX CAD user interface. T-FLEX Analysis utilizes the T-FLEX CAD Model Tree, Properties dialog boxes, command and menu structure, and many of the same mouse and keyboard commands, so anyone who can design a part in T-FLEX CAD can analyze it without having to learn a new interface.

Area of Application

Quick and inexpensive analysis often reveals non intuitive solutions and benefits engineers by providing them with a better understanding of product characteristics. Whether used in the mechanical, electromechanical, aerospace, transportation, power, medical or construction industries, T-FLEX Analysis can help to shorten development time, reduce testing costs, improve product quality, increase profitability, and cut time to market.

Quick and inexpensive analysis often reveals non intuitive solutions and benefits engineers by providing them with a better understanding of product characteristics. Whether used in the mechanical, electromechanical, aerospace, transportation, power, medical or construction industries, T-FLEX Analysis can help to shorten development time, reduce testing costs, improve product quality, increase profitability, and cut time to market.

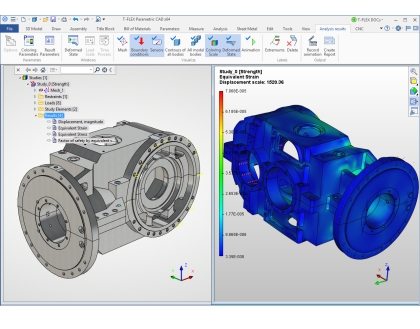

Structural Static Analysis

Structural analysis capabilities enable engineers to perform static stress analyses of parts and assemblies under various loading conditions. Static studies calculate displacements, reaction forces, strains, stresses, and factor of safety distribution. Static analysis can help you avoid failure due to high stresses. Various structural loads and restraints can be specified including force, pressure, gravity, rotational load, bearing force, torque, prescribed displacement, temperature, etc.

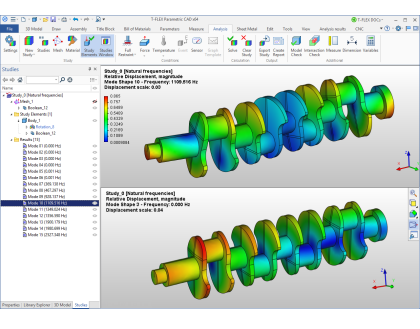

Frequency Analysis

Frequency Analysis determines a part's natural frequencies and the associated mode shapes. It can determine if a part resonates at the frequency of an attached, power-driven device, such as a motor. While resonance in structures must typically be avoided or damped, engineers may choose to exploit resonance in other applications. The typical applications include acoustical speaker design, aerospace structure design, bridge and overpass architecture, construction equipment design, musical instrument study, robotic system analysis, rotating machinery and turbine design, vibrating conveyor optimization and others.

Frequency Analysis determines a part's natural frequencies and the associated mode shapes. It can determine if a part resonates at the frequency of an attached, power-driven device, such as a motor. While resonance in structures must typically be avoided or damped, engineers may choose to exploit resonance in other applications. The typical applications include acoustical speaker design, aerospace structure design, bridge and overpass architecture, construction equipment design, musical instrument study, robotic system analysis, rotating machinery and turbine design, vibrating conveyor optimization and others.

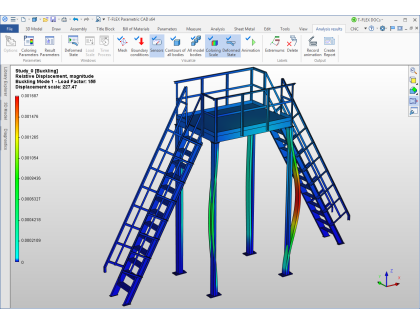

Buckling Analysis

Critical buckling load analysis examines the geometric stability of models under primarily axial load. It helps avoid failure due to buckling which refers to sudden large displacements and can be catastrophic if it occurs in the normal use of most products. Buckling analysis provides the lowest buckling load which is of interest and is usually used in such applications as automotive frame design, column design, infrastructure design, safety factor determination, transmission tower design, vehicle skin design and others.

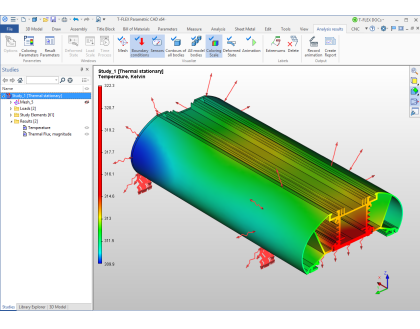

Thermal Analysis

Capabilities for simulating thermal effects include steady-state and transient heat transfer analysis. Thermal studies calculate temperatures, temperature gradients, and heat flow based on heat generation, conduction, convection, and radiation conditions. Thermal analysis can help you avoid undesirable thermal conditions like overheating and melting.

Capabilities for simulating thermal effects include steady-state and transient heat transfer analysis. Thermal studies calculate temperatures, temperature gradients, and heat flow based on heat generation, conduction, convection, and radiation conditions. Thermal analysis can help you avoid undesirable thermal conditions like overheating and melting.

Optimization

Designing and producing innovative products that meet performance criteria is a goal of every manufacturer. Using optimization techniques, engineers can improve a proposed design, resulting in the best possible product for minimum cost. Because your designs may have hundreds of variable parameters with complex interrelationships, finding an optimal design through manual iterations is hit-or-miss at best. T-FLEX Analysis relieves the burden of improving product designs by automating the iterative process of comparing performance against specifications.

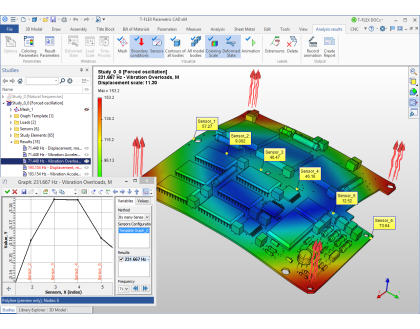

Frequency Response Analysis

Frequency response analysis determines the steady-state operation of a machine, vehicle or process equipment design subjected to continuous harmonic loading. As compared to linear transient stress analyses, frequency response analysis provides an easy, quick method in which the only inputs are a constant frequency and amplitude. For example, this analysis type could be used to determine the vibration effects of a washing machine with an unbalanced load or a bent wheel on a vehicle.

Frequency response analysis determines the steady-state operation of a machine, vehicle or process equipment design subjected to continuous harmonic loading. As compared to linear transient stress analyses, frequency response analysis provides an easy, quick method in which the only inputs are a constant frequency and amplitude. For example, this analysis type could be used to determine the vibration effects of a washing machine with an unbalanced load or a bent wheel on a vehicle.

Fatigue Analysis

Repeated loading and unloading weakens objects over time even when the induced stresses are considerably less than the allowable stress limits. Fatigue analysis is vital for products such as steel rails, beams and girders, which can experience mechanical failure under repeated or otherwise varying loads that never reach a level sufficient to cause failure in a single application. T-FLEX Analysis simulates fatigue-based failure and lets users design for durability by subjecting a product to cyclic applications of stress in order to determine its endurance limit and thereby ensure safety.

Analysis Results (Post Processing)

T-FLEX Analysis provides a comprehensive range of post processing operations with animation, various plots, lists, and graphs depending on the study and result types. The special reporting command helps you document your studies quickly and systematically by generating Internet-ready reports. The reports are structured to describe all aspects of the study.